Our Story

The Beginning

Started as a conventional machine shop manufacturing components for Gabriel India Limited at Kuruli Chakan Plant 1.

CNC Precision Era

Added CNC machines to manufacture precision parts, elevating our manufacturing capabilities.

Expansion - Plant 2

Acquired new land in Kuruli Chakan for Plant 2 to establish a dedicated CNC manufacturing facility.

Advanced Machining

Expanded with CNC and VMC machines, began supplying shock absorber parts and aluminium machining.

HPDC Technology

Diversified into High Pressure Die Casting with the first fully automatic 420T HPDC machine.

Land Acquisition

Purchased new land in Bhambholi Chakan for a state-of-the-art aluminium casting facility.

Capacity Enhancement

Increased die casting capacity with the addition of 250T and 420T HPDC machines.

Further Expansion

Added 420T and 180T HPDC die casting machines to meet growing demand.

New Facility

Completed Bhambholi Plant construction, consolidating all operations in one cutting-edge location.

Gravity Die Casting

Entered gravity die casting with 2 tilt pouring and 2 stationary gravity die casting machines.

Global Expansion

Commenced exports to USA of aluminium die cast parts, marking entry into international markets.

Industry 4.0

Launched digitization initiative to implement Industry 4.0 technologies with Fanuc Robots.

Our Mission & Approach

We are committed to delivering precision-engineered solutions that exceed customer expectations through continuous innovation and operational excellence.

Quality & Assurance

Quality System Commitment

We are committed to build & maintain IATF 16949 quality system in our organization to satisfy requirements & expectations of our valued customers through manufacture & supply of Aluminum die casting and precision machined components.

Continuous Improvement

We shall achieve excellence through continual improvement in all processes, emphasis on active involvement from all team members, comprehensive training programs, and reduction in wastages.

Technology & Innovation

Commitment to technology up-gradation and modern manufacturing practices ensures we stay at the forefront of precision engineering and deliver cutting-edge solutions to our clients.

OEM Approvals

IACPL is a manufacturing setup approved by all leading OEMs including Ford, Mitsubishi, Volkswagen, Toyota, Mahindra and Mahindra, and many more prestigious organizations worldwide.

Recognition & Awards

Certified excellence and industry recognition for quality, innovation, and manufacturing leadership.

BEHR Global Sourcing Partner Recognition

Global Sourcing Excellence – 2005

Recognized by BEHR for reliable performance and contribution as a global sourcing partner. Highlights long-term collaboration and supply chain excellence.

HYVA Quality Week Celebration Award

Appreciation for ACV Development – 2021

Awarded by HYVA in recognition of contribution to ACV development initiatives. Reflects commitment to quality, innovation, and continuous improvement.

MAHLE Certificate of Participation

Supplier Meet Recognition – 2024

Presented by MAHLE Anand Filter Systems for valuable partnership during 2023. Acknowledges collaboration and support toward sustainable growth.

MAHLE Performance Recognition Crystal Trophy

Driven by Performance

Premium recognition from MAHLE, reflecting engineering excellence and strong technical alignment with their standards.

MAHLE BEHR Excellence in Delivery

Runner-Up – Supplier Meet 2019

Awarded for consistent delivery performance and supply reliability. Demonstrates strong execution and adherence to customer timelines.

SIDBI Swavalamban Spirit Award

SIDBI Foundation Day – 2021

Presented by SIDBI to honor entrepreneurial and self-reliant spirit. Recognizes resilience, growth, and contribution to MSME development.

BEHR Global Sourcing Partner Recognition

Global Sourcing Excellence – 2005

Recognized by BEHR for reliable performance and contribution as a global sourcing partner. Highlights long-term collaboration and supply chain excellence.

HYVA Quality Week Celebration Award

Appreciation for ACV Development – 2021

Awarded by HYVA in recognition of contribution to ACV development initiatives. Reflects commitment to quality, innovation, and continuous improvement.

MAHLE Certificate of Participation

Supplier Meet Recognition – 2024

Presented by MAHLE Anand Filter Systems for valuable partnership during 2023. Acknowledges collaboration and support toward sustainable growth.

MAHLE Performance Recognition Crystal Trophy

Driven by Performance

Premium recognition from MAHLE, reflecting engineering excellence and strong technical alignment with their standards.

MAHLE BEHR Excellence in Delivery

Runner-Up – Supplier Meet 2019

Awarded for consistent delivery performance and supply reliability. Demonstrates strong execution and adherence to customer timelines.

SIDBI Swavalamban Spirit Award

SIDBI Foundation Day – 2021

Presented by SIDBI to honor entrepreneurial and self-reliant spirit. Recognizes resilience, growth, and contribution to MSME development.

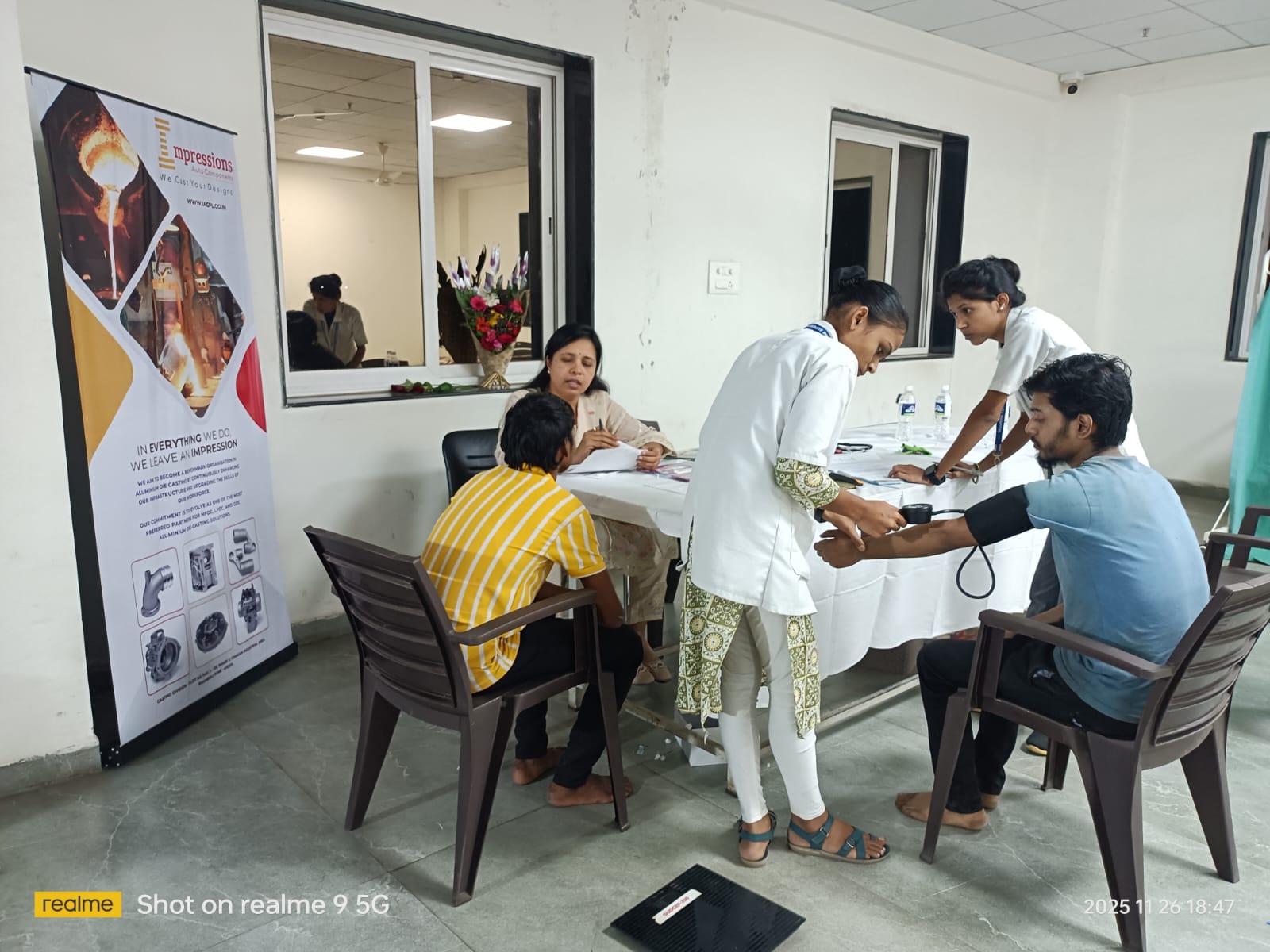

CORPORATE SOCIAL RESPONSIBILITY

We are committed to operate and grow our business in a socially and environmentally responsible way. We aim to create educated, healthy, sustainable and culturally vibrant communities. Our CSR initiatives focus on sustainable development of society and environment, making our planet a better place for future generations.

Medical Camp Bamboli

Organized a medical camp at Bamboli to provide free health checkups and medical assistance to the local community

Medical Camp Kurali

Conducted free health checkups and distributed medicines at Kurali for underprivileged communities

Runathon

Organized a community runathon event promoting health and fitness awareness

Tree Plantation

Organized a tree plantation event promoting environmental causes.